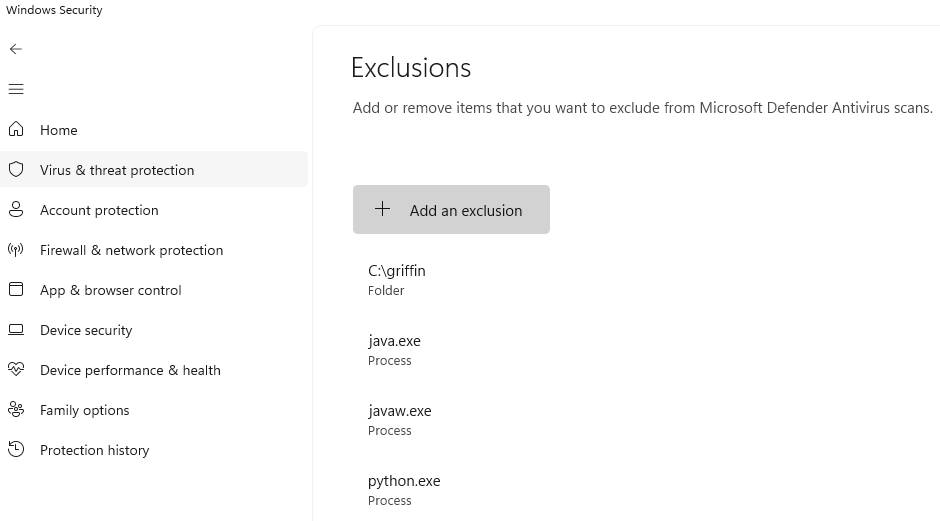

Control & Optimize Your Processes with Griffin AI Toolkit®

Griffin’s AI Toolkit provides a mature platform for control and optimization of plant processes. It supports a variety of industries to supplement their existing efficiency efforts with reliable technology. The system is open and customizable, providing immeasurable value for growing and evolving organizations.

Contact Us For A Free Trial

Automating the Mundate, Optimizing the Complex

Saves Millions of Dollars

Helps You Meet Your Target Goals

Better Flexibility & Turndown

Significantly Improves Efficiencies

A No-Code Solution to Build Your Digital Factory

Contact Us For A Free Trial

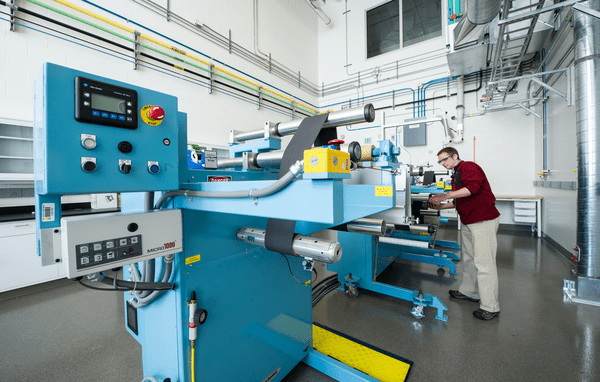

Continue the Digital Transformation

The Griffin AI Toolkit is fully compatible with your Griffin Dashboard Toolkit. It builds upon the dashboard with a plethora of AI tools to help automate and optimize your factory and process facility.

Continuous Process Improvement

Use the many tools in a no code format for logic, modeling, optimizing and diagnostics. The open design gives you control over how the solution is used and adapted over time.

Utilize Technology that Meets Your Needs

Use the library of data links to collect and organize data (OPC, Modbus, SQL Server, HTTP REST API, MQTT/SparkPlugB, HTTP WebSocket, OSI PI, and more)

Streamline Your Processes

Use the no-code application platform to process and analyze data and ultimately streamline your plant processes.

What We Do

“KSB enabled us to break away from sequence blowing. Got rid of 25+ operator-based sequences that were overkill. Blowers run more as needed now, with roughly 20-30% aux steam savings. And, we’ve been able to tune KSB rules and holds on blowers such that our units are as efficient and as clean as needed for baseload, as well as being inefficient and as dirty as needed to keep exit temps up at low loads for best ESP and SCR operation, the latter of which has made for better flexibility and turndown”.

A No-Code Solution to Build Your Digital Factory

Contact Us For A Free Trial- What exactly is a “digital factory”?

-

A digital factory is a centralized organization of digital data which is then used to create dashboards for users to track production processes, data analytics tools for investigating the production process, and digital models for continuous evaluation and optimization of the production process.

- We need a user-friendly interface that reduces costs but increases profit.

-

Our in-house experts and applied AI partners turn raw data into actionable insights for your operators and engineers to utilize.

- How do Griffin’s products help alleviate organizational knowledge barriers?

-

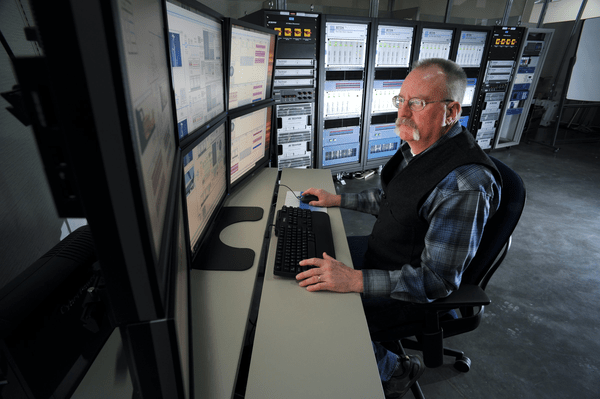

We strive to make your digital transformation experience as simplified and straightforward as possible and our team will be there every step of the way. Our artificial intelligence is reliable, open and customizable as well.

- What Is Adivarent Control® and how does it relate to my organization?

-

Adivarent Control is a term coined by Griffin Open Systems to represent this layer which is used to assist both the control system with complex tasks and operators with knowledge-based responses that require constant attention. This allows your operator’s tacit knowledge to be institutionalized across organizations.