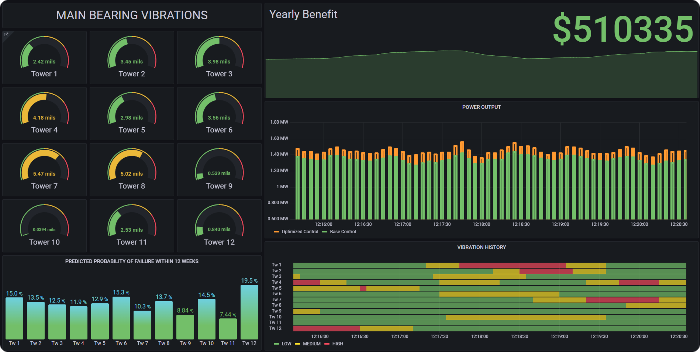

Optimize Your Business with Griffin’s Dashboard Toolkit

Our free Dashboard Toolkit has what you’re looking for to start your journey toward a digital factory. Griffin Open Systems’ no-code, easy-to-use Dashboard helps lower cost, drive up profit, improve efficiencies, and streamline your process.

Download the Free Dashboard

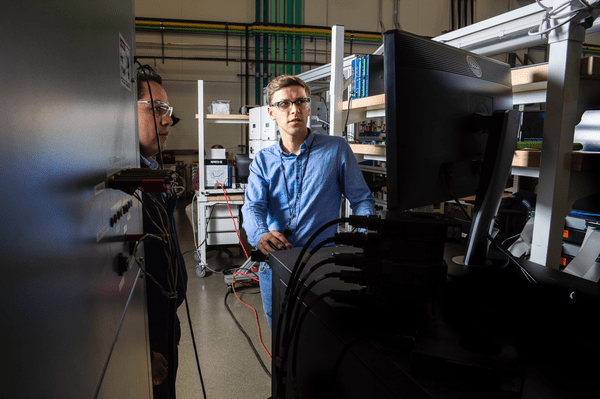

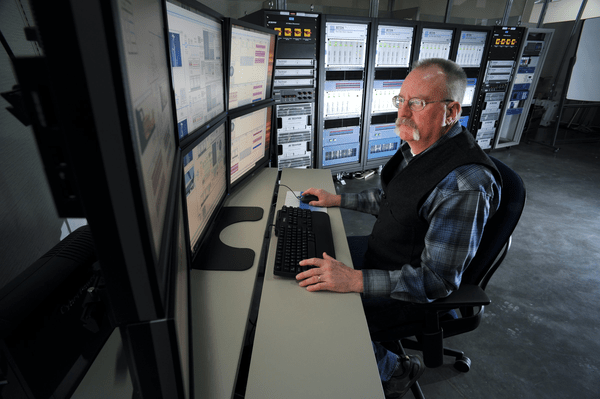

Bridging the Gap Between Control Systems and Operators

Saves Millions of Dollars

Helps You Meet

Your Target Goals

Better Flexibility

& Turndown

Significantly Improves Efficiencies

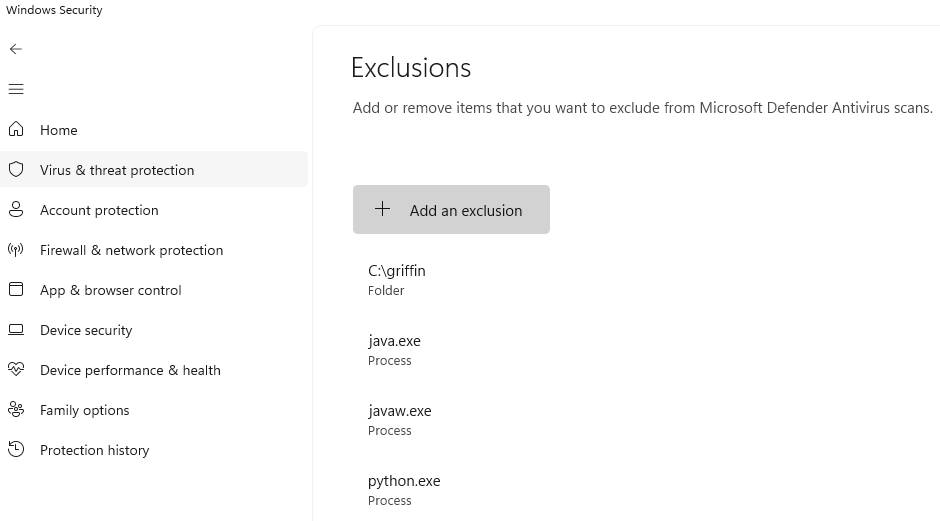

A No-Code Solution to Build Your Digital Factory

Download Our Free Dashboard

Build a Better Facility

We help you build dynamic dashboards in minutes with pick and place tool.

Streamline Your Processes

Use the no-code application platform to process and analyze data.

Utilize Technology that Meets Your Needs

Use the library of data links to collect and organize data (OPC, Modbus, SQL Server, HTTP REST API, MQTT/SparkPlugB, HTTP WebSocket, OSI PI, and more)

Easily Integrates With the Griffin AI Toolkit

The transition to the Griffin AI Toolkit is a seamless beginning to optimizing business and plant processes when you’re ready to upgrade.

What We Do

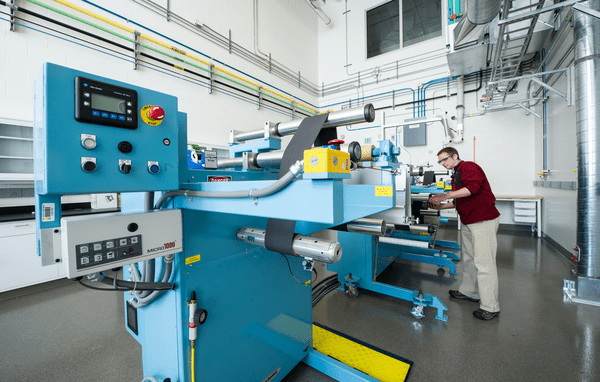

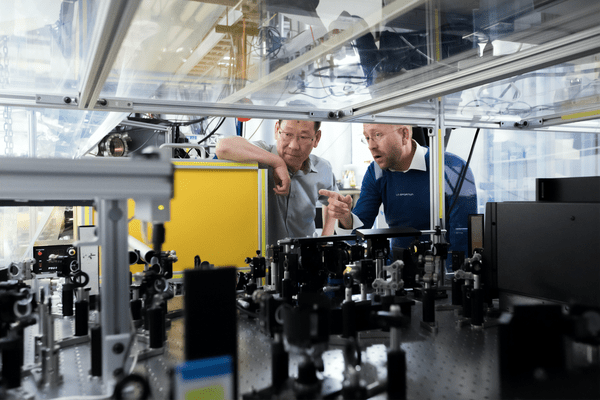

Since 2013, Griffin Open Systems has been optimizing traditional plant processes to support operators and their existing control systems.

Through a partnership with Taber International, LLC, whose personnel have worked for 40+ years with electric utilities and other industries on achieving efficiency gains and emissions reduction, we are able to collaboratively create efficiencies for customers like you.

“As a systems integrator, the Griffin Dashboard has revolutionized my workflow. Its no-code interface allows me to create tailored client prototypes in mere hours, an efficiency that was previously unattainable. Its open design coupled with an extensive range of data links facilitates seamless integration of multiple systems, transforming raw data into actionable process knowledge. What truly sets Griffin’s Dashboard apart are its deep customization options. They allow for the encapsulation of proprietary knowledge in a highly intuitive user interface. This sophisticated platform has made rapid prototyping a reality, and its real-time testing capabilities mean that new process control and automation strategies can be deployed seamlessly, without disrupting existing systems.

The free version is an excellent starting point for my clients, offering a risk-free opportunity to experience the value of this dynamic tool firsthand. It’s not just a game-changer in the landscape of process control and optimization – it’s the new industry 4.0 standard.”

Jwal Soni

Field & Development Engineer, Taber International LLC

A No-Code Solution to Build Your Digital Factory

Download Our Free Dashboard- What exactly is a “digital factory”?

-

A digital factory is a centralized organization of digital data which is then used to create dashboards for users to track production processes, data analytics tools for investigating the production process, and digital models for continuous evaluation and optimization of the production process.

- We need a user-friendly interface that reduces costs but increases profit.

-

Our in-house experts and applied AI partners turn raw data into actionable insights for your operators and engineers to utilize.

- How do Griffin’s products help alleviate organizational knowledge barriers?

-

We strive to make your digital transformation experience as simplified and straightforward as possible and our team will be there every step of the way. Our artificial intelligence is reliable, open and customizable as well.

- What Is Adivarent Control® and how does it relate to my organization?

-

Adivarent Control is a term coined by Griffin Open Systems to represent this layer which is used to assist both the control system with complex tasks and operators with knowledge-based responses that require constant attention. This allows your operator’s tacit knowledge to be institutionalized across organizations.