Combustion Optimization

Achieving Optimal Control of Combustion Processes

Combustion is complex – as such controlling combustion processes can seem daunting. Griffin’s Combustion Optimization System (COS) utilizes advanced AI to develop specialized and accurate models of each unique system to:

- Reduce emissions

- Improve heat rate

- Achieve other process objectives

Griffin’s COS has a proven track record of maximizing performance as existing systems have demonstrated 0.5% to 1% improvement in heat rate and reduction in emission rates in excess of 20%.

The highly complex and sensitive nature of combustion processes makes it one of the most challenging systems to control in a coal-fired power plant. Behaving almost as its own living entity with each process having its own individual characteristics and behavior, managing and controlling such systems is difficult. Griffin’s Combustion Optimization System (COS) uses many advanced AI methods available within the Griffin AI Toolkit to develop highly specialized and accurate models of each unique system to reduce emissions, improve heat rate, and achieve other process objectives.

How We Make It Happen

There is no “one-size-fits-all” method to gaining real and repeatable improvements from combustion optimization systems. Griffin’s COS application approach has been developed and refined over more than 50 years of experience providing combustion optimization solutions. Building upon the proven Griffin COS template of reliable and robust control, each COS application is tailor-made to address the unique characteristics of the subject system. Advanced AI modeling and optimization methods are used to represent process complexities and take advantage of each and every existing opportunity; from subtle damper adjustments, to shifting whole operating conditions within acceptable ranges, all prospective improvements are leveraged to provide maximum performance benefits.

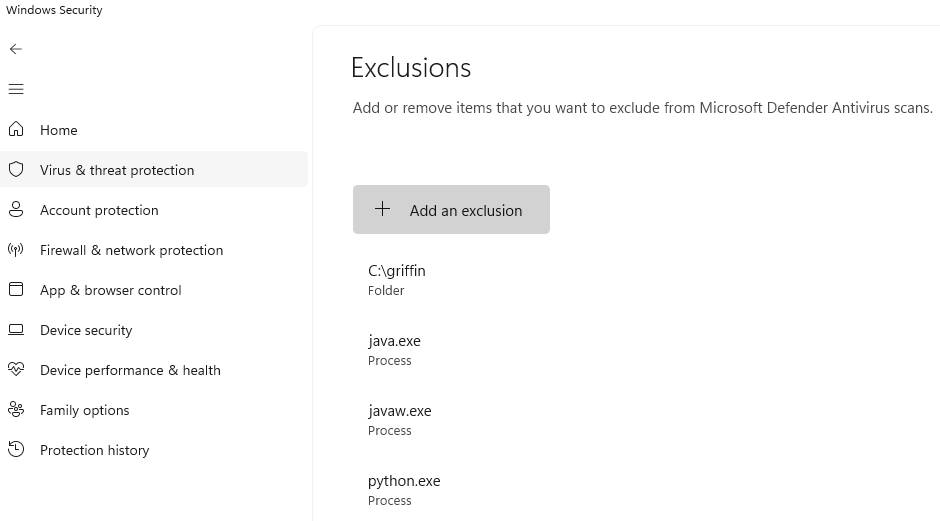

Existing site knowledge from those who know your system best – your engineers and your operators, often spanning decades of operation – is then formalized and rapidly implemented within the Griffin no-code platform to further complement the advanced AI components in place within the COS. This process results in a highly customized and fully relevant optimization system capable of providing control benefits to the system in as little as 1 – 2 weeks. As the AI components continue to learn and adjust from observing real-time operations, observed benefits continue to improve automatically over time.

Expected Improvements

Griffin COS applications can be configured to realize one or many of a number of

performance objectives. Common benefits include:

- Reduction of NOx emissions up to 40%

o Often eliminates the need for SCR system installation - Heat rate improvements of 0.5% – 1%

o Environmental benefit from reduced CO2 emissions - Avoidance of unplanned outages

o Greater reliability, dispatched sooner, and lower O&M costs - Enhanced alarm condition management and resolution

- Consistent unit control across all operating crews and system conditions

A Griffin COS is a valuable addition to any combustion process with a proven record of improving multiple aspects of process performance. Regardless of system complexity or existing limitations, benefits can be obtained through this powerful application. Contact us today to learn more about your options!