AI in the Steel Industry

Published: November 20, 2020

The steel industry is unique in that manufacturers are constantly battling between product quality and maintaining price competitiveness. This creates a challenging landscape, especially given the number of variables that can affect both steel quality and price. However, this large number of variables and the need to maximize process output, while keeping operating expenses in check, make AI (artificial intelligence) a prime candidate for steel manufacturers looking to operate their mills at peak efficiency.

Reheat Furnace Optimization with AI

Reheat furnaces are widely used in the steel and metallurgical industries to heat metal slabs to the proper temperatures for rolling, forging, or extruding. Despite there being many different types and designs of reheat furnaces they all face common challenges such as:

- Inefficient energy usage

- Low granularity/difficult to use control systems

- High reject rates due to unacceptable slab temperatures after extraction

Leveraging an AI control system optimizer to ensure optimal temperature setpoints can help address all three of those common challenges. To learn more about temperature setpoint optimization in reheat furnaces, download our whitepaper, “Temperature Setpoint Optimization in Steel Reheat Furnaces Using Open Architecture Neural Network and Modeling Software”.

How to Select AI for the Steel Industry

One of the most common challenges steel manufacturers face when optimizing their processes is dealing with complex and difficult to use control systems. Often times these systems don’t offer high enough granularity of data or are simply not designed with the operator in mind. As such, when selecting an AI solution to supplement the control system, ensuring it can integrate data flows easily in a way that is easy for operators and engineers is key.

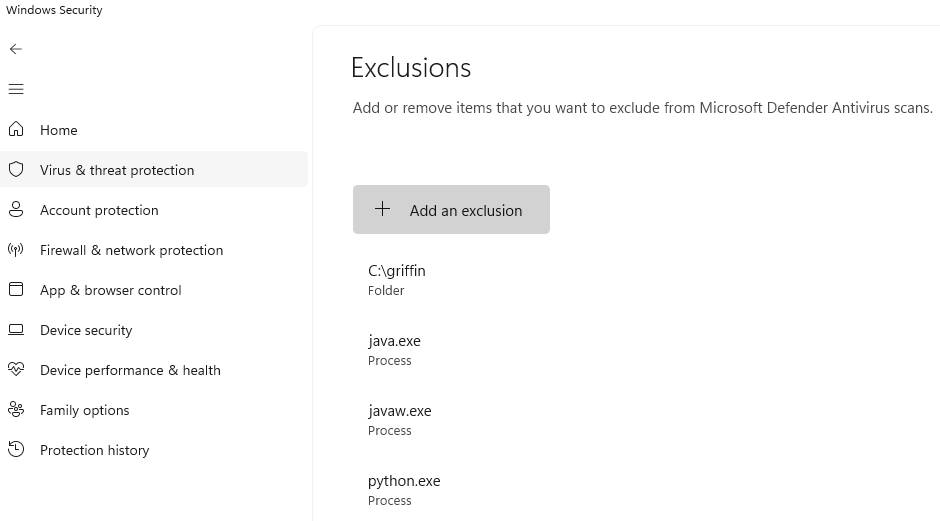

Many AI tools are now built with a no-code UI allowing operators and engineers to quickly and easily model, test, and implement optimizations for processes. Other important features to look for are systems that can leverage multiple data flows. The promise of AI is that it can bring many disparate data flows together to help reach optimal setpoints, and ensuring that the AI solution you are working with isn’t a “black box” or has limited integrations is of the utmost importance.

To learn about our solutions for the steel industry click here: Griffin AI Toolkit in Steel and Reheat Furnaces.