Artificial Intelligence in Mining & Minerals

The application of artificial intelligence in mining modeling and optimization to fine-tune control of the rotary kiln can result in:

- Increased product quality and production rates

- Reduced emission rates

- Enhanced slagging management

- or a combination of these objectives

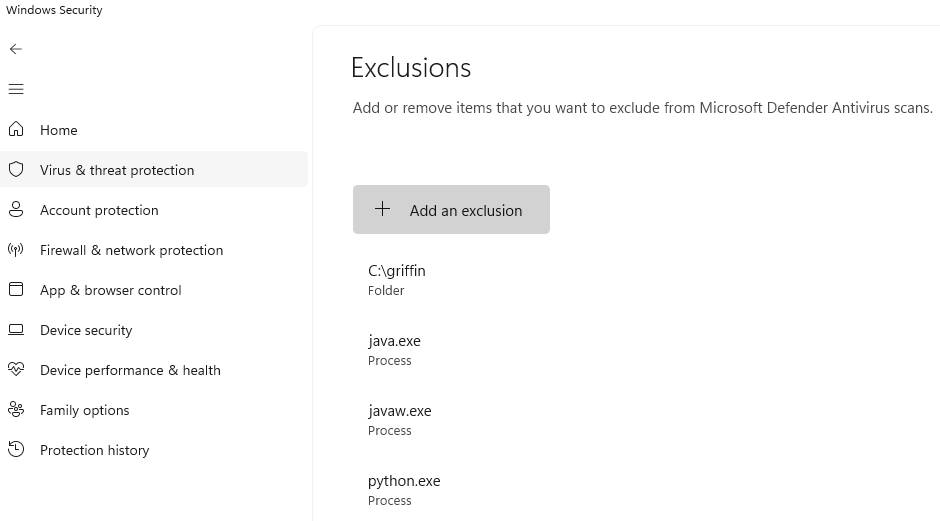

Using multiple advanced artificial intelligence methods, the complex combustion and chemical processes unique to an individual kiln can be learned and accurately represented for optimization and real-time control. Our system automatically implements small changes to the manipulatable operational parameters available to operations at regular periods to achieve defined objectives in the long term. Furthermore, within the Griffin AI toolkit, your expert knowledge can be developed to work hand-in-hand with the AI capabilities of the system to ensure unique circumstances are addressed appropriately. Our system will provide your organization with the confidence you need that control will not deviate from accepted practices.

The Griffin AI Toolkit® Advantage

The Griffin Toolkit offers mining & minerals manufacturers a no-code user interface with a number of tools to model and analyze existing processes – as well as implement closed-loop process control to optimize those processes in real-time, without reprogramming PLC logic. Our scalable solution allows manufacturers of any size and level of automation to leverage fully automated processes and reap the benefits of AI process optimization.

Contact us to learn how the Griffin Toolkit can help your business.